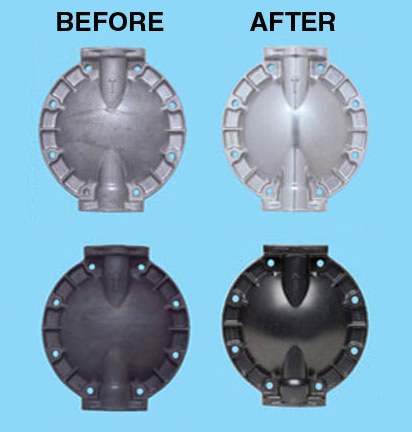

Burnishing/Polishing

Machined parts have burrs, castings have flash, extrusions and stampings have sharp and rough edges. The manufacturing process typically leaves behind some little imperfections that spoil the appearance and in some cases make the product difficult to handle.

These manufacturing imperfections may even negatively impact the seal or final assembly of the product. Hand finish detailing of a product is expensive and adds the risk of scratching or marring due to increased handling. The more economical solution is vibratory de-burring. This process smoothes edges and removes small residual imperfections that cause problems.

You will find the best vibratory de-burring and polishing service at Fort Wayne Anodizing. Our pair of 20 cubic foot automated De-Burring Vibratory Finishers use a steel media for de-burring and polishing castings or a plastic non-marring media to gently erase imperfections on extruded or machined components.

Here are the advantages:

Here are the advantages:

- Improves Fit and Seal

- Removes Undesirable Residual Metal

- Creates a Smooth to the Touch Edge

- Provides a “Fine Finished” Look and Feel

Let us combine de-burring with Chromate, Industrial Hardcoat or our own Across the Spectrum Color Anodizing and give your final product great visual appeal, higher reliability and strength, and most importantly, an edge over the competition.

“Durable, Reliable Products with a Premium Look = More Sales, Happier Customers and Premium Pricing”